BLT-FS /BLT-NFS is developed for freight station, large shopping mall, airport and other places. It adopts a new design concept, set safety, comfort, energy saving, environmental protection, human design in one.

BLT-NFS is not applicable to forklift trucks.

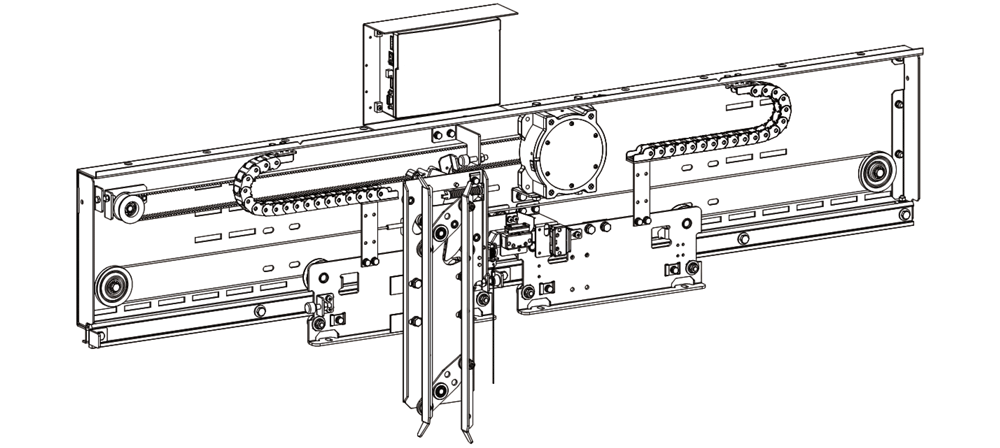

The new generation of BLT-FS/BLT-NFS uses a more reasonable layout, small machine room and no machine room, save room space, thus directly reduce the user's civil construction cost, and bring more design space to the building. The high-strength car design makes it capable of lifting weight in various working conditions. Precise weight switches strictly control the load, and the ground is made of non-slip steel plates, which generate enough friction to prevent people from slipping or cargo from sliding even when contaminated with oil. High hardness cast iron floor can withstand high loads without deformation.

(1) BLT-FS/BLT-NFS dragging system uses VVVF vector control to make start, accelerate, deceleration and stop the elevator very stable and comfortable, greatly improving the leveling accuracy, reduce the noise and vibration, and energy saving and environmental protection.

(2) Using permanent magnet synchronous motor frequency conversion drive door machine system, with low speed, high efficiency, constant torque, high control precision, low noise, small vibration, maintenance free and other characteristics;

(3) The synchronous door knife with integrated door lock function is adopted to prevent falling into the well due to pulling the door, and the synchronously opening and closing of hall and car door is truly realized;

(4) The upper and lower keeping devices are used to prevent the door from separating from the guide device and avoid the danger of falling into the well for human reasons

English

English  简体中文(中国)

简体中文(中国)  Español

Español  Русский

Русский